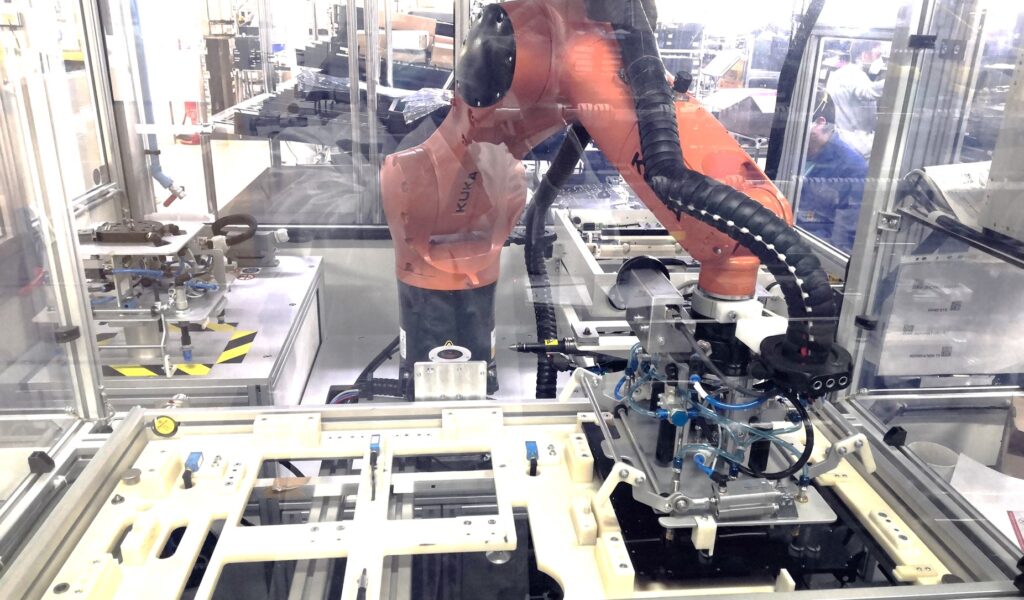

This automated electronics assembly project was a first robot integration for our customer !

Drawing on our technological and sectoral expertise, we supported this innovative client in its project with a robotic cell for automated electronics assembly and screwing.

Challenge

Enable customers to be delivered in quality and on time by automating low value-added screwing tasks, while enhancing the employer’s image

Customer issue

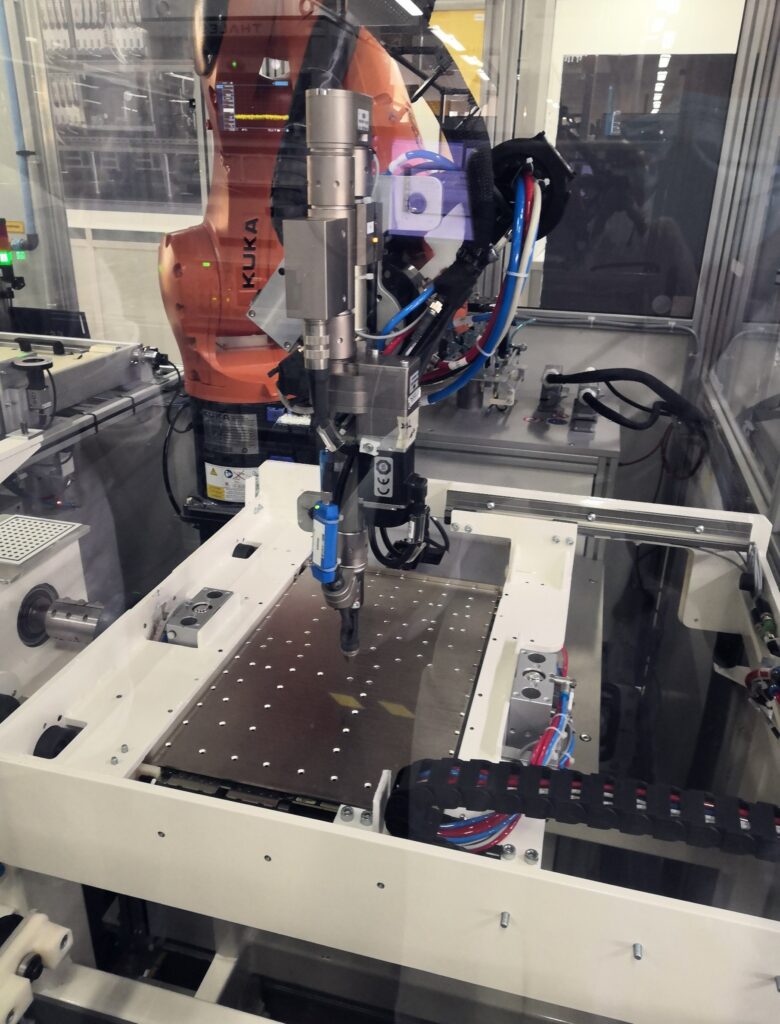

- Automate a low value-added operation carried out by qualified personnel (screwing in 300 screws per module)

- To adapt to a growing production demand

- Manage quality problems (manual assembly, low precision screwdriver, etc.)

- Reduce work in hidden time during in series assembly

AKEOPUS' solution

- Quickly propose a customised solution based on AKEOPLUS assets, automated and personalised to the customer’s environment (ESD zone, electronic test bench)

- Interface with an existing production line, without compromise.

- Enhance the image of the factory with innovation and new technologies

About AKEOPLUS

AKEOPLUS, the first 360° robotic agency, brings together a team of experts specialized in robotics and industrial vision. With nearly 20 years of experience and primarily composed of engineers and PhDs, we closely collaborate with end-users and integrators, designing pragmatic and daring solutions for their robotic projects. Our vision is to harness the best of technologies by developing innovative and sustainable solutions to enhance industrial performance.

Are you looking for an automated electronics assembly solution ? Contact us !