Discover the different bin picking robot use cases !

Drawing on our technological and sectoral expertise, we supported all these customers, and more, in the implementation of their bin picking robot solution.

Bin picking robot applications

Payload : 1kg

Accurate detection of part position in bulk by 3D registration on CAD/DFN,

Trajectory optimization for reliable part pick-up,

95% bin emptying,

Cycle time at 8s/part,

Robot:

FANUC R2000iB

Sensor:

3D Sick Scanning ruler

Payload : 200 g

-

Robot repositioning to pick up the part on an intermediate station for 1 mm deposit,

-

Dedicated ergonomic HMI for learning different types of parts,

-

Emptying of the tank at 95%,

-

Learning time for a new reference: about 2 hours

-

Cycle time 15 to 20 sec/parts,

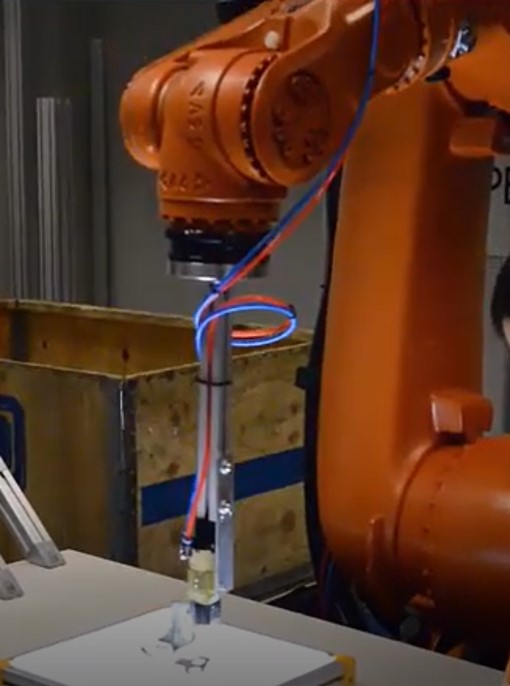

Robot:

Kuka KR60

Sensor:

3D TOF IFM – 2D IDS (accuracy)

Payload : 10 to 20 kg

Adapting robot trajectory to avoid collision with the bin,

Smoothing of trajectories for deposit on conveyor,

Double mechalectro magnetic gripper,

Robust gripper for simultaneous gripping of 2 sanded parts,

Ergonomic HMI for starting and stopping production,

90% bin emptying,

Cycle time between 10 to 15 sec per part,

Robot:

FANUC R2000iB

Sensor:

3D TOF IFM

Payload : 20 kg

Adapting robot trajectory to avoid any collision of the gripper with the bin and extend the gripper’s life,

Robust mechanical gripper dedicated to the food industry,

Ergonomic HMI to start and stop production

95% bin emptying,

Cycle time 10s/piece,

Robot:

Staubli RX160 HE

Sensor:

AKEOPLUS 3D

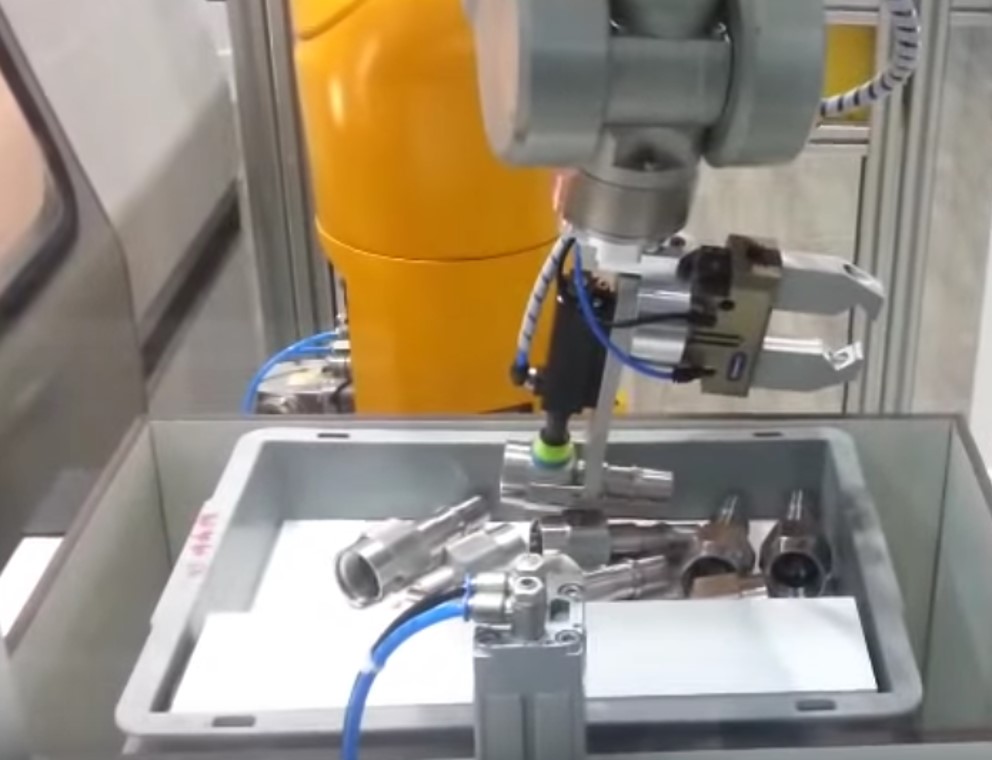

Payload : 500 g

Application: machining, sanding, inspection,

Precise detection of the part position in bulk by 3D registration on the CAD/DFN

Trajectory optimization for reliable part gripping,

Trajectory adjustment for workpiece insertion into the bore

Robot:

Staubli TX30

Sensor:

3D IDS ENSENSO

Payload : 100 g

- Gripping of plastic parts and bulk bags

- Customized triple gripper: small parallel jaw, large parallel jaw, and suction cups for gripping items of different sizes and shapes

- Sensor and vision algorithms for 3D detection on conveyor,

Robot:

FANUC M20iA

Sensor:

2D Sensor – 100 Hz – 5 MPix

Payload : 100 g

-

Workpiece pick-up on conveyor belt with dynamic vision tracking,

-

Pneumatic gripper,

-

Ergonomic HMI for starting and stopping production,

-

Learning time for a new reference: approx. 2 hours,

-

Extremely fast cycle time of 1 sec/part,

Robot:

Staubli TP80

Sensor:

High-frequency 2D camera – 100 Hz – 5 MPix

About AKEOPLUS

AKEOPLUS, the first 360° robotic agency, brings together a team of experts specialized in robotics and industrial vision. With nearly 20 years of experience and primarily composed of engineers and PhDs, we closely collaborate with end-users and integrators, designing pragmatic and daring solutions for their robotic projects. Our vision is to harness the best of technologies by developing innovative and sustainable solutions to enhance industrial performance.

Are you looking for a bin picking robot ? Contact us !