Turnkey solutions

We offer a range of proven turnkey solutions, providing a hassle-free experience for industrial customers

What is bin picking ?

“Bin picking”, in robotics, is the process of taking pieces out of a disordered state in order to grasp and organize them at another location. So bin picking involves locating and retrieving a part from a volume that contains many others, through the joint action of a robotic arm controlled by one or more sensors or systems (such as vision, vibratory bowl, or feeder).

Bin picking can be done at the beginning of a production line (such as a box of parts), in the processes (where it allows a pick-and-place operation from the downstream process), or at the end of line (such as for packaging products, palletization).

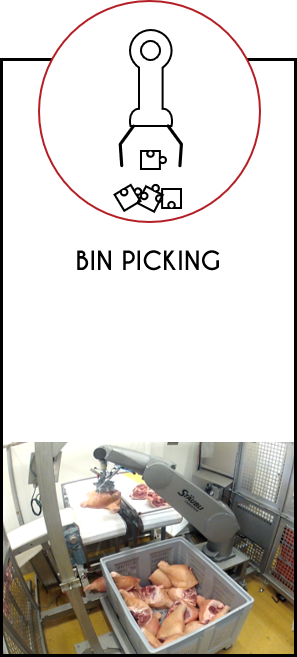

Bin Picking

Our bin picking solution with robots offer to pick up items directly from bins or containers. The turnkey solution allows to take parts, with a robot equipped with one sensor, no matter if the input packaging is a pallet or a bin.

Automated bin picking provide significant advantages, including faster processing times, lower costs, higher accuracy, and improved safety.

To tailor our solution to your needs, we assemble your turnkey solution by carefully selecting the most suitable elements from our network of partner robots, sensors, and technologies.

Gains

- Optimises or even reduces packaging by reducing the amount of empty space transported

- Reduces buffer stock (if the unjumbling serves as a supply to a process)

- Eliminates custom mechanization

- Saves time when feeding a machine

- Increases autonomy when the automated line can be kept supplied with parts for a long time before an operator call

- Increases flexibility, in particulary during changeovers of new parts

- Decreases musculoskeletal disorders associated with repetitive, sometimes heavy, manual handling

- Reduces low-value added operations (such as restocking, loading trays, etc.).

Our bin picking solution

Housing

Compact and modular design (Robot, Sensor, Cab)

Adaptable layout to the environment, boxes and rooms

Mesh, Polycarbonate, or opaque walls

Don't see your specific needs among our six use cases?

No problem.

With several hundred systems currently in operation, we have a proven track record of developing 100% custom solutions that address the unique needs of our clients.