No-Code

AKEOPLUS is focused on simplicity and cost-effectiveness by allowing modularity in streamlined industrial applications through the robotics software.

No-code programming

Entire industrial processes are built on the user-friendly interface with pre-designed blocks and actions.

AKEOPLUS is for everyone and goes straight to the point: so you don’t need to be a roboticist, developer, or programmer. Simple to understand and easy to use, reuse, and share with its self-explanatory program.

- Cloud staging

- Simulation

- Deployment

- Version control

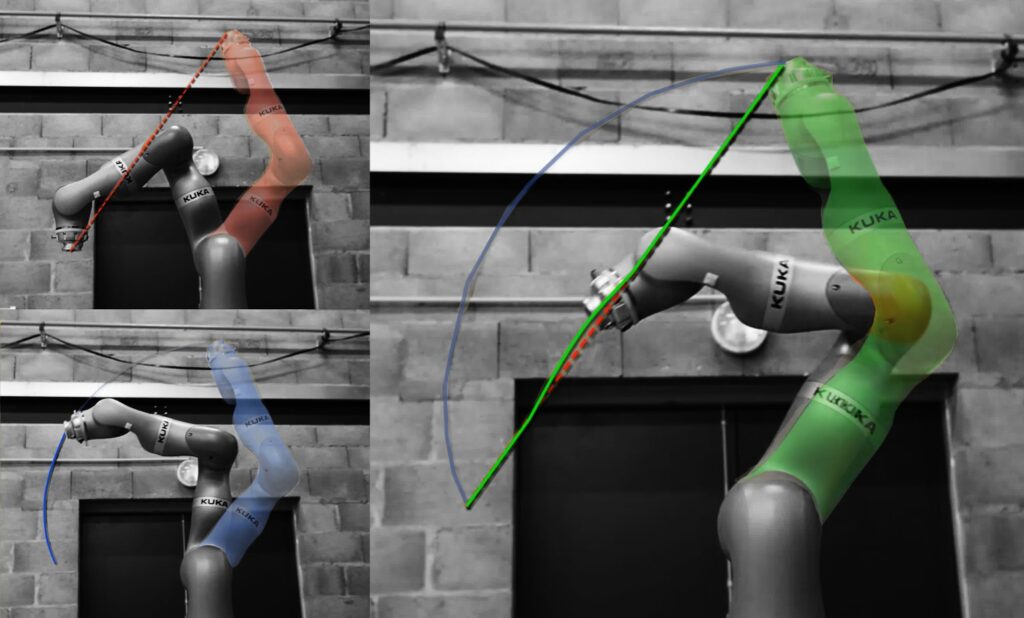

Hassle-free robotics

AKEOPLUS finds the optimal robotic solution for the case-by-case needs and constraints. It recommends an optimized hardware set and streamlined actions and trajectories to meet a given industrial need.

This unique feature drastically reduces development time and integration and reconfiguration costs. Teams can focus on their added-value mission and develop new know-how.

- Automatic configuration

- Trajectory optimization

- Hardware recommendations

DATA VISUALIZATION & CLOUD SUPERVISION

The robotics software includes connectivity for shop floor data in order to be accessible from anywhere, on any device, through an easy-to-navigate system.

The custom dashboard provides decision-makers with visibility to assist them in managing production, quality, and maintenance operations. Processes can be continuously improved with realtime data visualization.

- Customizable dashboard

- Production supervision

- KPI Analytics

FLEXIBLE HARDWARE INTEGRATION

AKEOPLUS is encoded with a strong, core philosophy of versatility. It is designed to ensure easy integration of current and future tools and technologies.

It can be used to adapt solution integration to a wide range of hardware references. Robotic systems can quickly evolve in step with processes and company developments.

- Hardware agnosticism : PLCs, robots, sensors, vision systems, tools, and much more.

POWERFUL INTELLIGENCE INTEGRATION

Robotics can be easy until faced with a changing environment or new elements. AKEOPLUS automates unpredictable tasks with vision and/or AI.

Easily add appearance and dimensional control algorithms to the automated solution.

- Vision library interoperability

- Smart vision systems

- AI integration interoperability

SHOP FLOOR CONNECTIVITY – LEGACY SYSTEMS

Shop floor connectivity is included in the robotics software and platform with standard proven communications.

So vertical integration down to the shop floor avoids mistakes by streamlining applications:

- External hardware connection

SECURITY & SERENITY

Data and Intellectual Property are protected. Moreover, access is restricted and managed by admin profiles.

AKEOPLUS makes data management secure through systematic user authentication. It also keeps your know-how safe with smooth and seamless integration of new and future updates.

- Cybersecurity

- Audit trail

- Role-based permission management

SUPPORT & NO-CODE COMMUNITY

AKEOPLUS is backed by a full, dedicated team to advise and support on industrial projects.

From the simplest, most common projects to the most complex and unusual.

Get customized support from AKEOPLUS and / or work closely with the no-code community but also with peers. Share your technical feedback, successes, and obstacles.

- Training

- After Sales Services

- Community

- Ticketing

- FAQ