This product has been designed to control robotic adhesive dispensing systems, and is now a real industrial success worldwide !

Because robotic adhesive dispensing systems can leave some defects, we have developed for our customer a sensor that analyses 100% of the adhesive deposits !

Challenge

To guarantee the safety level of the vehicles produced thanks to a control of the completeness of the applied mastic beads, while reducing the production costs

Customer issue

- Automated control of the quality of sealant application

- Standardise the solution to adapt it to the human and economic resources of the factories

- Maintain the autonomy of the operators and make quality control more reliable

- Find an end-to-end partner capable of offering a turnkey solution and integrate the solution worldwide

AKEOPLUS' solution

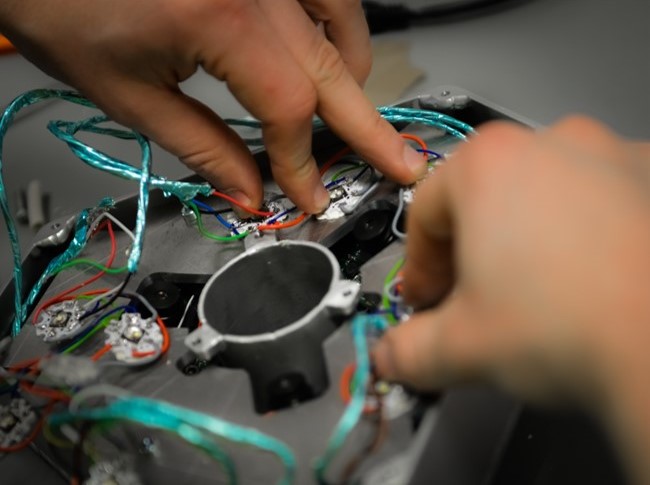

- Propose a functional proof of concept to the different factories and validate the product concept

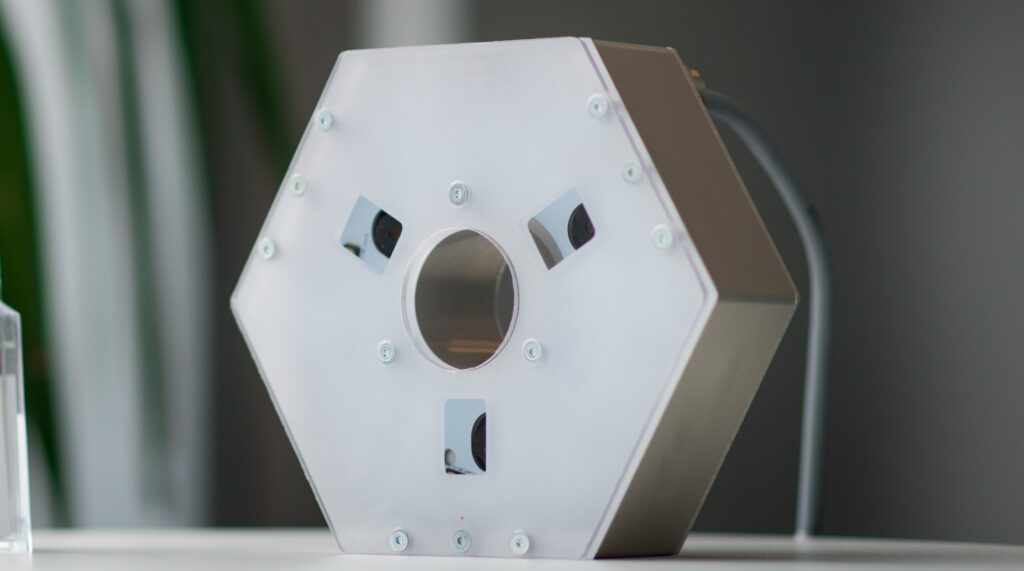

- Produce a mass-produced system with an architecture that can be adapted to different factory configurations, providing automated control of 100% of the cords deposited

- Guarantee easy integration and support for integrators

About AKEOPLUS

AKEOPLUS, the first 360° robotic agency, brings together a team of experts specialized in robotics and industrial vision. With nearly 20 years of experience and primarily composed of engineers and PhDs, we closely collaborate with end-users and integrators, designing pragmatic and daring solutions for their robotic projects. Our vision is to harness the best of technologies by developing innovative and sustainable solutions to enhance industrial performance.

Are you looking for a vision tool to control robotic adhesive dispensing systems ? Contact us !