This predictive maintenance solution was a real innovation for our customer !

Drawing on our technological and sectoral expertise, we supported this innovative client in its project with the development and industrialization of dedicated predictive maintenance solution.

Challenge

Generate a competitive advantage through a digital solution that provides a complementary service of expertise to build customer loyalty.

Enable plastic injection moulders to move towards operational excellence by maximising the productivity and durability of their tooling.

Customer issue

Coming up with a complete strategy to gain market share by offering new value-creating services

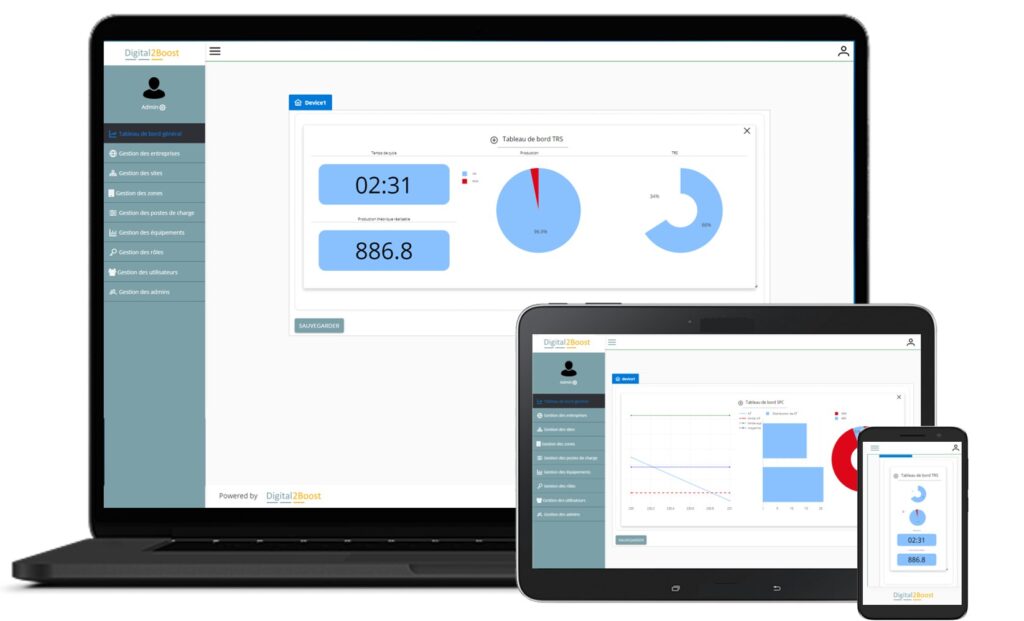

Offering a complete turnkey solution with a simple and innovative hardware and digital offering

Enabling customers to reduce downtime and energy consumption, and to increase their synthetic efficiency rate

AKEOPLUS solution

Improve the relevance of prediction for maintenance actions by adding artificial intelligence, while guaranteeing the security of the acquired data

Embed the intelligence as close as possible to the customer’s machines in order to secure production

Have a solution that can be easily integrated into customers’ different production environments

About AKEOPLUS

AKEOPLUS, the first 360° robotic agency, brings together a team of experts specialized in robotics and industrial vision. With nearly 20 years of experience and primarily composed of engineers and PhDs, we closely collaborate with end-users and integrators, designing pragmatic and daring solutions for their robotic projects. Our vision is to harness the best of technologies by developing innovative and sustainable solutions to enhance industrial performance.

Are you looking for a predictive maintenance solution ? Contact us !